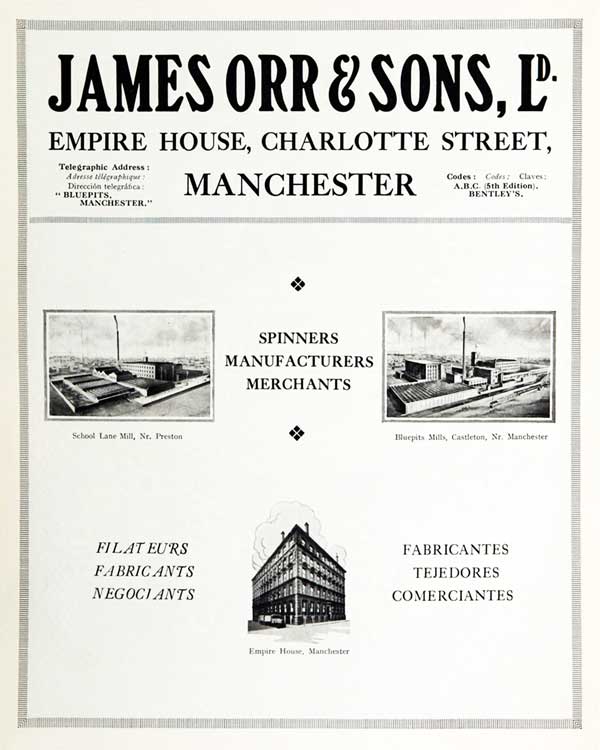

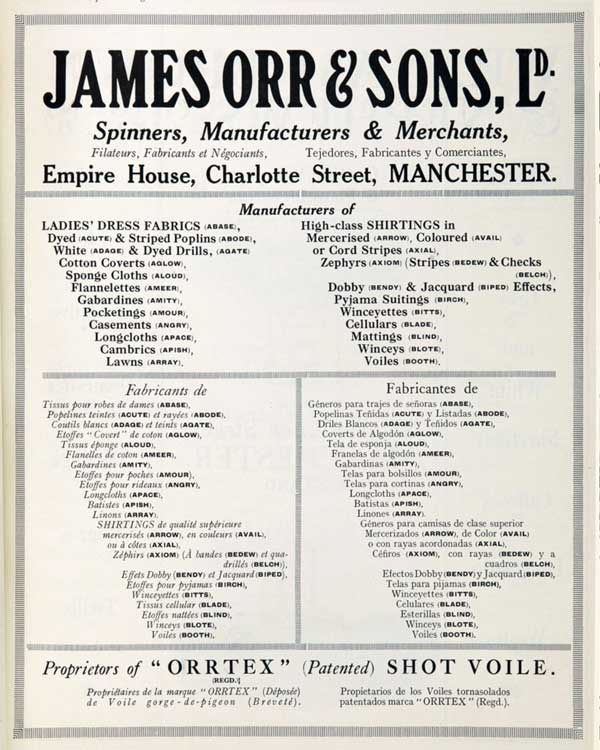

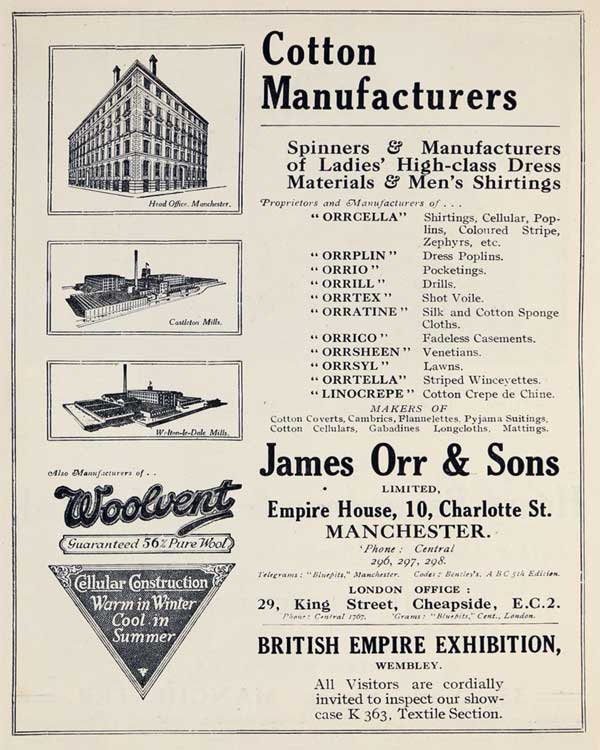

Orr Cotton Mills

Lancashire

I’m going to be the first to admit, I actually know very little about the Orr Mills, and since no one is left alive, that I’m aware of, its going to be one of those “I wish I had asked more…” type of tales.

I have started to find a few images, due to electronic archiving that is going on, and as I find more, I will add information.

There is a video of the A.S. Orr Bamber Mill, that was filmed by Lancaster University for their “On The Move” education series, in the late 1970s. I actually watched it not knowing it was my family mill, until the very end where they showed the finished cloth being loaded on lorries for delivery, and there was A.S. Orr and sons written on the side. Efforts to track that video down have failed, since the series was mothballed a long time ago.

What I do know, is my father, G C Orr, worked at the Bamber Bridge Mill, and I do have memories of visiting it as a child. I understand my grandfather, Angus Orr, had a long standing business relationship with Sir Cuthbert Clegg, ( Clegg shows up on the Orr Board of Directors ), as they loved new technology together. One of these Clegg/Orr mills was visited by the Prime Minister of England on one of his northern tours.

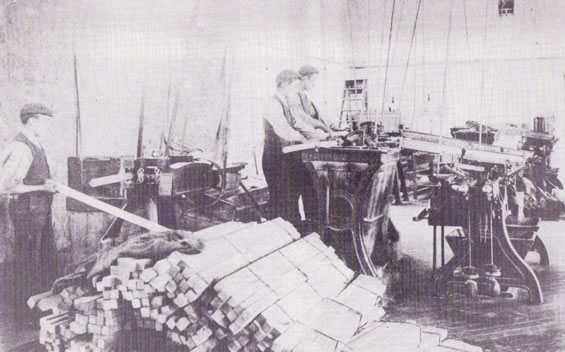

The work goes on … Mr Macmillan and his party watch a machinist at work in the making-up room. On the far left is Sir Cuthbert Clegg, managing director of shore Mills.

PM’s mill visit not just for the camera

It’s not all that often that high-flying politicians visit Rochdale, except when a general election in in the air.

It was all good fun and a good photo opportunity for the London lensmen following in Mr. Blair’s footsteps.

Years ago, politicians didn’t always visit towns when they felt an election was in the offing.

In 1959, Harold Macmillan had only been in office for two years, with a further three to go, when he visited the Rochdale district on April of that year.

He was given an enthusiastic welcome with hundreds of people lining the road from Whitworth to Littleborough where he spent about two hours at the Shore Mills of E Clegg and Son Ltd.

Accompanied by his wife, Lady Dorothy, the Prime Minister was cordially greeted by Sir Cuthbert Clegg and Lady Clegg and were then introduced to Mr and Mrs Angus Orr, Mr R C Lees-Milnes, Mr G C Orr, and Mr D Bolton, with whom was Mr Tony Leavey, MP for the Heywood and Royton division.

The introductions over, Sir Cuthbert led the way into the cardroom and from there through the various spinning rooms, winding and beaming department, the pillerless weaving shed and into the warehouse to see the finished products.

Foremen in each department were presented to the Prime Minister who was also intorduced to long-serving employees and operatives whose forebears had worked at the company.

In one of the spinning rooms, Me Macmillan had a word with Mrs Rachel Kershaw, aged 72, who had worked at the mill sicce 19002 and was the mother of 10 children, five of whom worked at Shore mill.

A surprise awaited Mr Macmillan in the mechanics shop where he met Mr Hector Mils who invented the rock anchor used to secure Mulberry harbours which were emplyed during the Second World War.

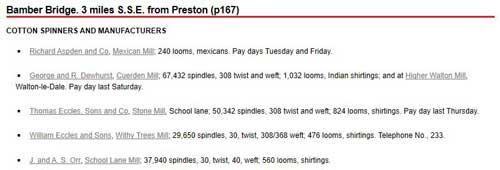

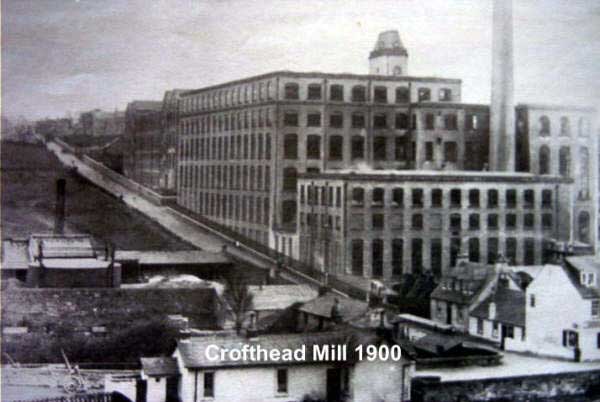

Crofthead Mill, Neilston

This mill was built for cotton spinning on the banks of the Levern by the Orr family after the disastrous fire of 1883 which burned down the original building erected by Stewart, Orr & Co in 1792.

By 1830 Crofthead was the biggest producer of spun cotton in the county and remained with the Orrs until 1914 through a series of alliances i.e. R.F. & J.Alexander of Glasgow (1859), English Sewing Co (1898) when it was taken over by Tootal & Co Ltd.

In its time it attracted thousands of workers to Neilston with good living and working conditions.

The mill, finally owned by the large Coats Viyella thread producers, closed in 1993.

————–

The next mill on the Levern is Orr’s Crofthead Mill, the first of six cotton mills which used the Levern water. Crofthead Mill was built in the 1790s (perhaps by Stewart, Orr and Co.) as a cotton-spinning mill. At first the company had a problem with the supply of water. Because of the number of factories using the water from Waterside to Crofthead, the supply fell badly in summer. The problem was solved by the formation of a consortium of the companies concerned, who agreed to meet the cost of increasing the supply of water by building dams at the Long Loch, the Harelaw and the Commore, and compensating the farmers affected for the loss of land involved. A control point was built at Commore Dam. As all the other firms went out of existence it eventually fell to Crofthead Mills to effect care and maintenance of the dams.

By 1830 Orr’s Crofthead Mill was the biggest producer of spun cotton of the six companies on the river and was continuing to expand. In 1859 Orr and Co. combined with R.F. and J. Alexander and Co., who operated the mill at Duke Street, Glasgow, on the Molendinar Burn. The Neilston mill became known as R.F. and J. Alexander and Co. Ltd of Neilston and Glasgow, and traded worldwide in finished cotton thread products.

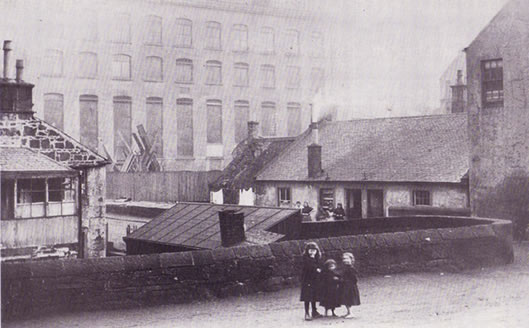

Number 1 mill was burned down in 1883, and from then on a series of new mills was built, the last being the spool-turning department, completed just before the end of the century. The spool-turning department became uneconomical and was closed in the early 1960s. This factory, quite a large five-storey building, was demolished in 1968.

In 1898 Alexander’s joined the combine called the English Sewing Cotton Company Ltd; the Duke Street mills were closed in 1906 and the whole business was concentrated at Crofthead. This brought quite an influx of workers from Glasgow, who settled mainly in the new property on Holehouse Estate which had just recently been completed; many, however, continued to travel from Glasgow. At this time the firm was employing between 1250 and 1500 workers. The Orr family maintained an active interest in the business through Mr. Archibald Orr until 1914. The company now operates under the name of Tootal and Co. Ltd.

Orr’s mill benefited greatly from having a railway station and goods yard nearby (Neilston Low Station was just across the main road). The fact that coal could be brought virtually to the doorstep was a major factor when steam power became the in thing. Alas, steam power is now a thing of the past and so too are the Low Station and goods yard. The mills now depend on electricity for light and power.

Mill water supply from the River Levern

Spool turning in the wood workshop

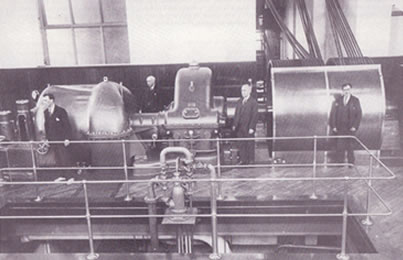

Introduction of the new Steam Plant to power the mill

Why Cotton in Lancashire?

The cotton industry came about in the northern climates of Scotland, Lancashire, Cheshire, Nova Scotia because of the right amount of humidity in the air. Cotton is a highly flammable product to spin, and couldn’t be spun in the drier southern states or counties, as static could build up too easily. Workers on the spinning floors would have to work in bare feet, or socks originally, and wear or use nothing that could cause a spark. Fires did still happen, hence the disasturous fire at Crofthead in 1883.

The cottage wool industry had already created the skills, and with the trade routes to the New World and Egypt, cotton imports came into demand. Water power was needed, hence the mills were on rivers, then steam power, and then electric power.

Tower top from the Bamber Mill, all that is left today.

With the events of WWI cutting off supply lines, and reducing the work force, followed by WWII doing the same, the industry certainly went through tough times in the 20th Century. But the final straw was the import of new cheaper nylon products in the 50s, where a similar dress made in Cotton would cost 10 pounds, and nylon version would only cost 2 pounds. There was an attempt to tax nylon to protect the cotton industry, but that didn’t last.

Cotton started to be relegated to speciality products, but eventually most if not all the cottons mills of Lancashire have now closed down. Ironically there is a new demand for more natural products again, but cheap imports from India and China are now the competition.

I am proud to see Orr Textiles in Texas, USA. They are making a successful come back.